Solar Products Home Page

Key Features

- 11.6 KWH

- Up to 100A discharge

- Replaces "48V" Batteries

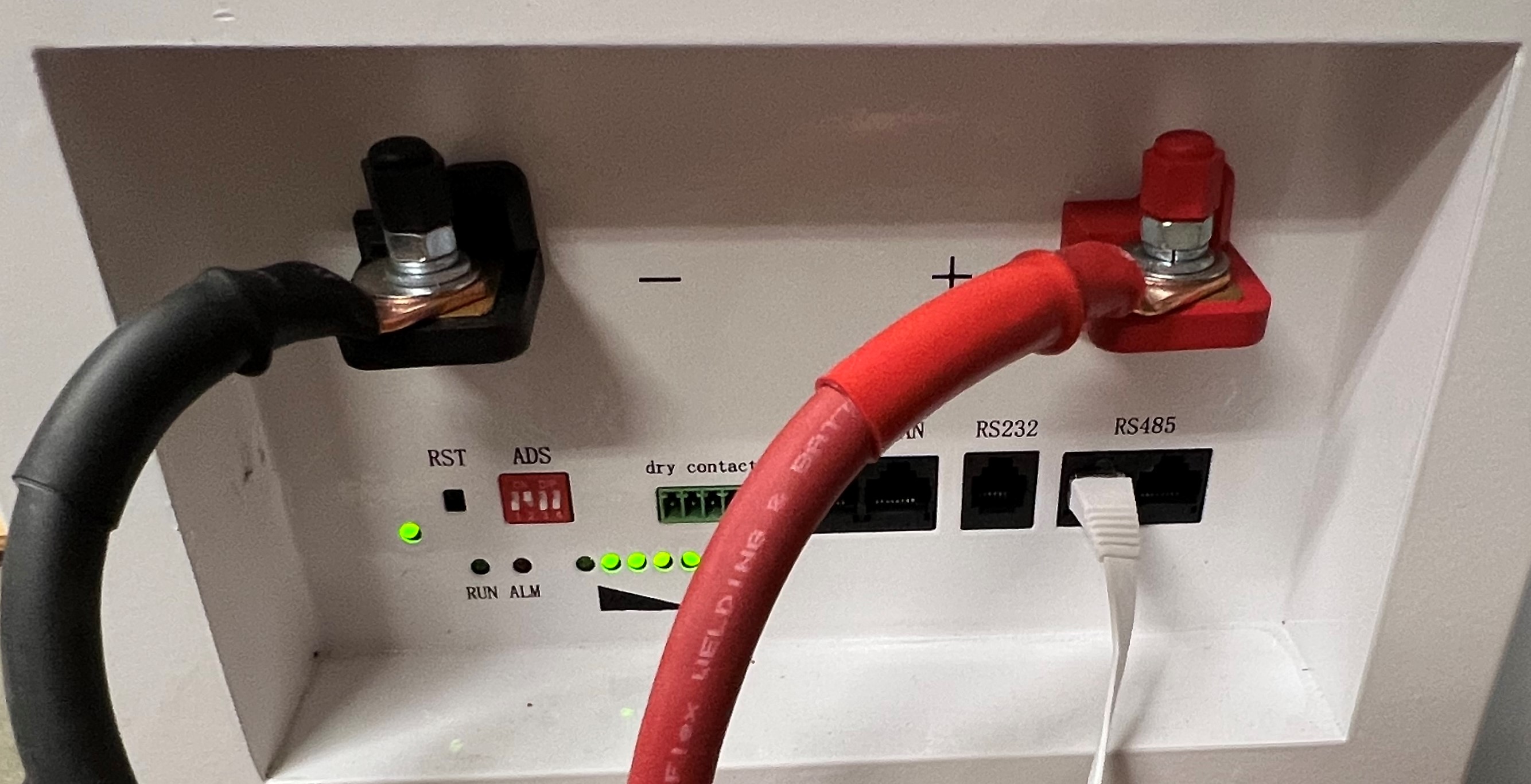

- Built in BMS with over current protection, status port

- Simple parameter entry for your controller

- Safe LiFePO4 cell construction

- RS485, RS232, CAN options for communication

- Up to 16 units can be operated in parallel

- LED display for charge level

- Battery life - more than 6000 cycles [80% capacity remaining]

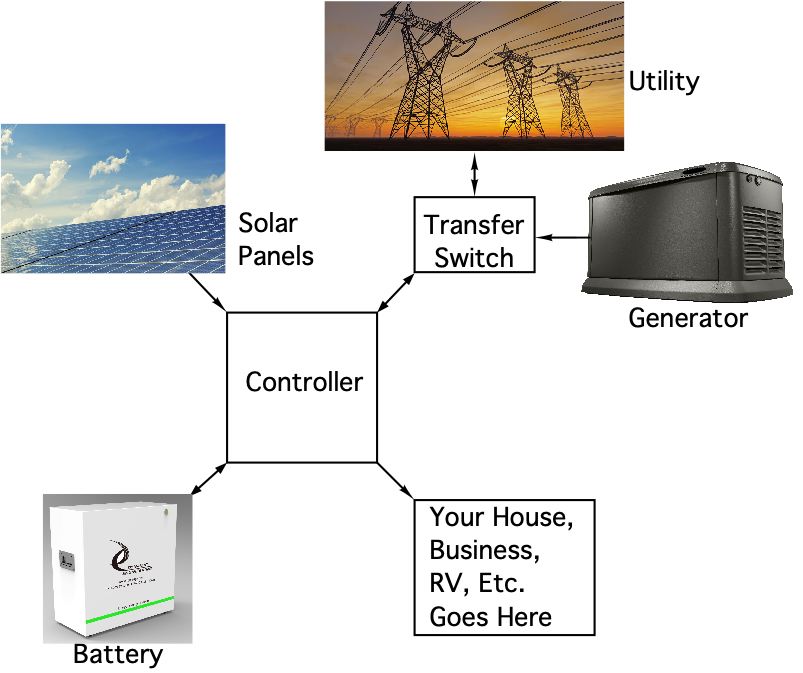

Batteries are an important element for a complete solar installation. Battery power is available instantly. The generator will take some time to come on-line. By having batteries in your system, you can use the controller to run from battery during Time of Use periods [TOU] when the utility cost is much higher. The batteries can pay for themselves by allowing the use of lower cost stored power during the more expensive time.

When the utility goes off-line the battery can be on-line quickly enough not to notice the transition [with a good controller]. In a system with a generator the battery can run the system until at a lower programmed limit. When the lower voltage threshold is achieved; the generator is started to run the system and recharge the battery. The generator can recharge the batteries faster than the batteries would be discharged by the system. This behavior means the on-time for the batteries is much longer than the on-time for the generator. Natural gas or Propane is expensive, and the generator is more efficient when run at the higher rate for a shorter time. Batteries make this possible. During daylight the PV may be able to run the load and recharge the batteries depending on the size of the array. Another important benefit is batteries are quiet.

Solar Panels & Inverter Photovoltaic panels have multiple PV cells strung together within the panel. The cells convert light from the sun into electricity. Each cell produces a small amount of power. The panel joins them and creates a larger voltage / current. The cells are delicate and the panelization also provides protection against the elements. Some panels are single sided and others are bifacial to capture both direct and reflected light energy. The panels create DC power which is combined and used with an inverter to convert to AC power for load and grid use. The power from the solar panels can be optimized by local conversion to a common higher DC voltage. Shading from clouds or trees etc. can be mitigated with this approach. In addition, the higher voltage reduces the wiring requirements for transmission to the inverter. The inverter in many cases is part of the controller. The efficiency of the inverter is very important as the losses in this element reduce the power output of the solar panels.

Generator A secondary source of power is a great idea in a solar / alternate power system. The batteries can be sized to last for as long as you want, and it will be a finite length of time. The weather can stay dark longer than the batteries can stay charged. The power can be out for weeks. With a standby generator and batteries your system expense can be minimized and utility maximized. WIth the batteries sized to get through the night, and the generator settings in the controller programmed to work with the battery, the system can operate mostly on battery / solar input and only have the generator running for a fraction of the time. Generac and Honeywell make nice units. I recommend rat proof ones [don´t ask me why]. We have a Honeywell unit and added the external switch control to allow the controller in our system to switch it on and off. Propane and natural gas are the best choices. The generator will need to create enough power to run the load including charging the batteries. Depending on what appliances you have, the power to generate could be substantial. Since the batteries will eliminate long periods of idling - pick a large enough one. Be able to run the oven, dryer, heat pump, well etc. with enough left over for battery charging. Without the batteries you need to decide not to turn everything on [all at once] and reduce the fuel load during lower power usage times.

Transfer Switch is the mechanism used to control the path of electrical energy flow. Many generator installations include an "automatic transfer switch" or ATS to sense when the utility power is not present and to switch to generator power. The switch acts as a relay with a normally closed and normally open function. The relay will have multiple units working in parallel to switch the number of power rails coming to the load. Two for 240V, Three for three phase etc. Businesses with higher capacity equipment tend to use 3 phase power. Dynamic Engineering has this type of power to support our SMT equipment - the reflow oven and placer in particular. Other equipment uses 240 or 120. Our standby generator / transfer switch are 3 phase devices as a result.

Some controller units include separate inputs for generator and utility and have an internal transfer switch eliminating the requirement for an external device. Depending on where the generator is placed compared to the utility power connection it may make sense to use the external switch even when the controller has its own. The transfer switch must be sized to handle the expected current from the utility or generator.

Load: the end point device(s) consuming the power. The load can be your house, RV, portable device, company etc. The load to be supported will define the size of the system. The stored power in the battery bank divided by the load defines the run time from the battery bank. If your system is intended to be operated by PV panels the size of the load will determine the array of panels required. The type of power used by the load, 120, 240, three phase etc. will affect the architecture of the system design to properly provide the output you require. If the load is existing, a logging meter can be used to measure the KW vs. time. the graph will show the peak power requirements and provide an idea of the average load. With sufficient battery storage the solar array can be designed for the average load and the battery bank handle the peaks. Your installer should have access to the logger for the measurement. The devices usually use inductive coupling and are used without being invasive to your current system. With the data for the load, you can make intelligent decisions about sizing your system.

Maintenance All systems require maintenance. With alternate or augmented power systems like Solar Arrays it is no different. An obvious example is cleaning your panels. Solar Panels are mounted outside and get dirty. Birds, dust, pollen, pollution etc. are deposited onto your panels. Sometimes a good hard rain will remove most of the deposits but frequently you need to clean them. We recommend using a telescoping pole plus brush with sprayers built in. If used with well filtered water you can clean without using any additives and not have trouble with streaking. I put my personal cleaning system together with components from Amazon. Two hoses, water filters mounted to a miniature hand truck, and the telescoping pole / brush with sprayers combination. Also added a shutoff valve at the pole since up on the roof and nice to have control over the water. In the winter we get away with not needing to clean as we do get heavy rain. In the spring, summer and fall we do need to clean based on how dirty the panels get. If you pay attention to the power developed before and after cleaning you can fine tune your own strategy for how often to do the cleaning in your environment. For my set-up every couple of months is sufficient.

A not so obvious maintenance is keeping the batteries charged and discharging them once in a while. See your manual for the particulars. Allowing the battery to sit in a discharged state for too long will degrade the battery life. With a quality LiFePO4 battery and thousands of cycles you are not wearing the battery out by using it in any appreciable way. Setting up for TOU - using the battery during the expensive utility time - will accomplish exercising the battery and reduce your energy cost.

Check your connections on a periodic basis. If you are close to the ocean or in a high humidity climate you may need to clean the contacts every so often. Corroded contacts will not transfer as much power directly affecting efficiency and can become dangerous. With an increased voltage drop from the corrosion more power is expended in the joint creating excessive heat which can start a fire etc. Be careful with this item - high voltages exist within your system. Refer to the manual for the equipment or hire an installer to do this part of your maintenance.